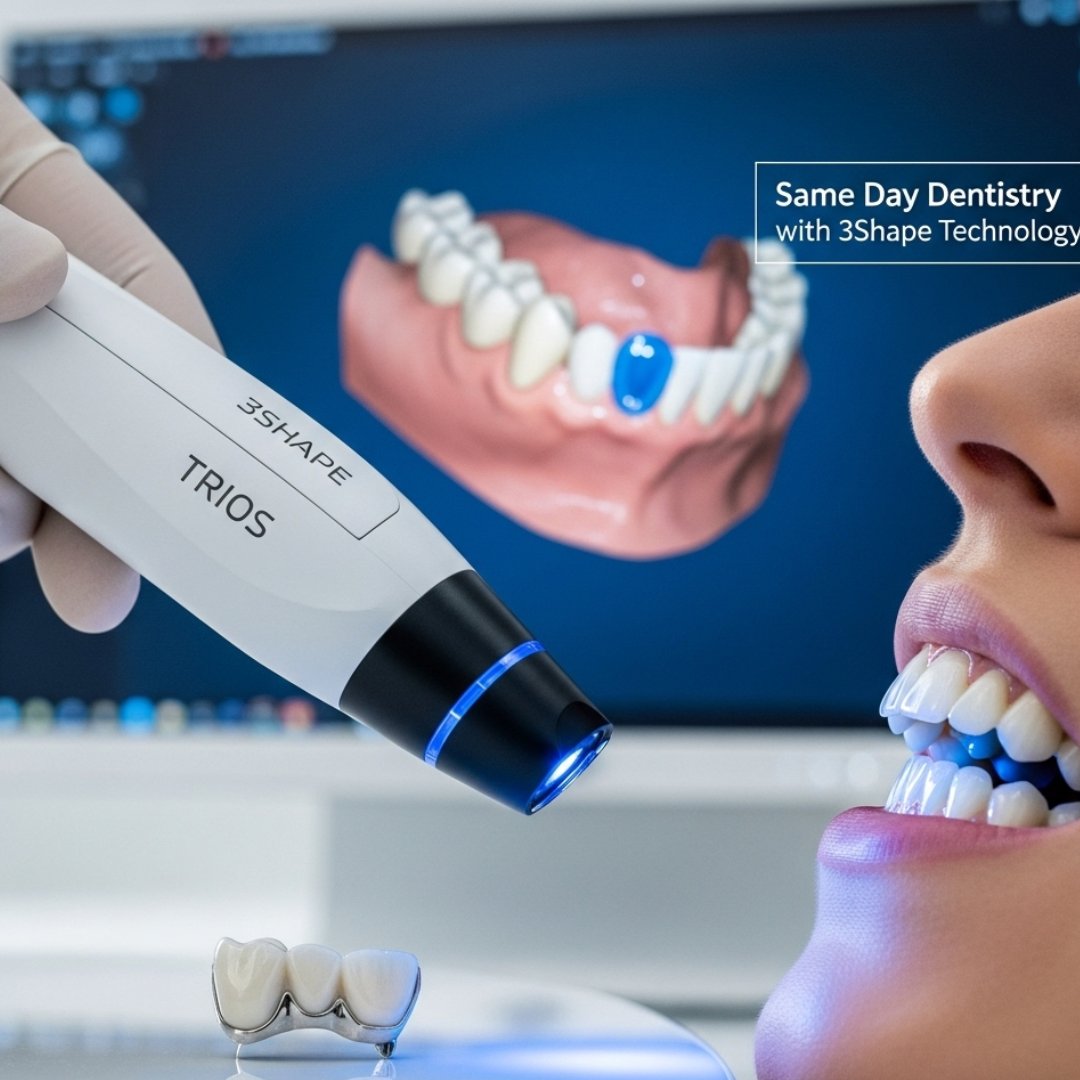

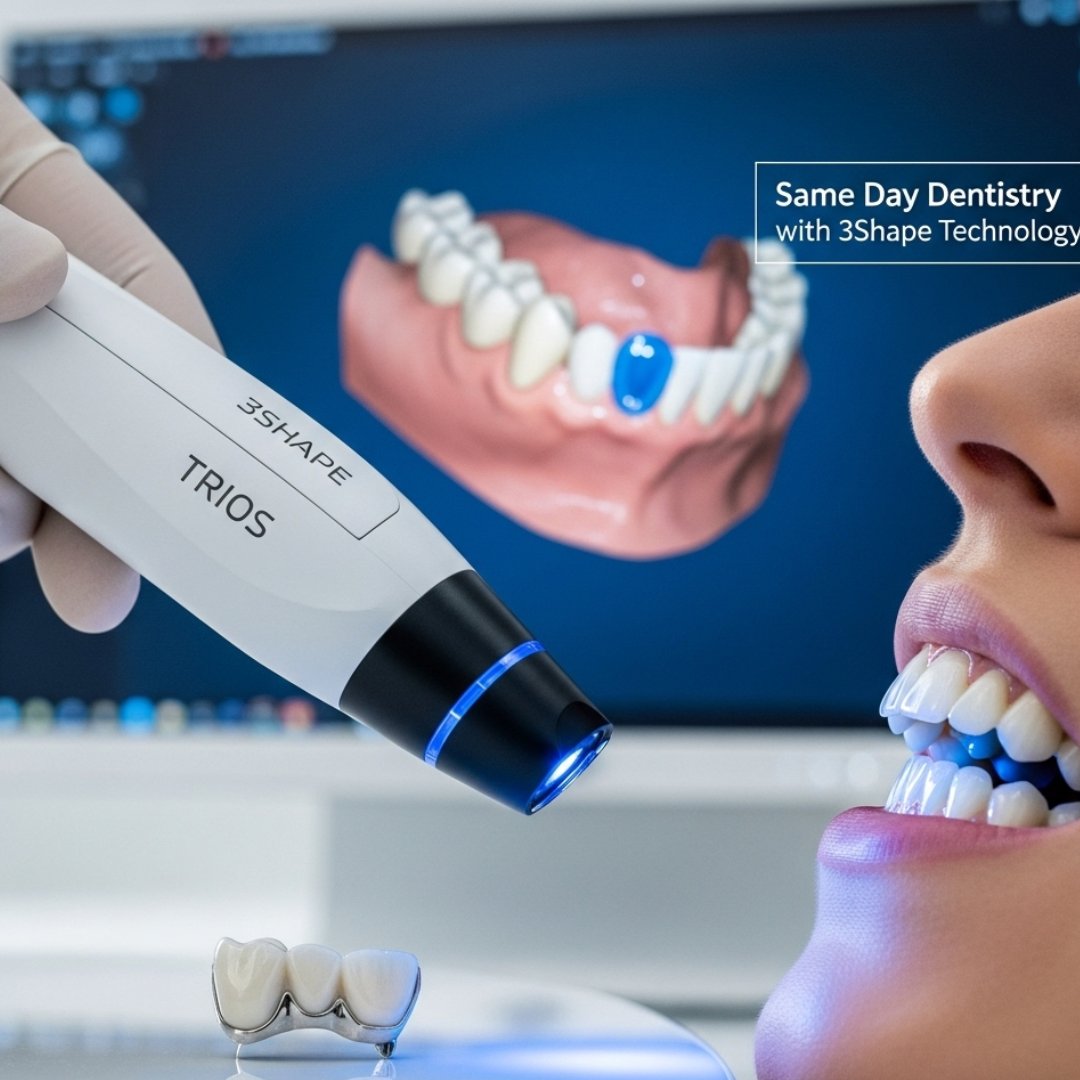

Same Day Dentistry with 3Shape Technology

Time is precious, and in 2024, more dental practices embraced same-day dentistry using 3Shape TRIOS and in-house milling technology. No more temporary crowns, no more waiting weeks for your next appointment.

Your dentist uses the TRIOS scanner to create a digital model of your tooth. That data goes straight to an onsite milling machine, which crafts your permanent crown right there in the office. All in a single visit.

This tech-forward approach doesn’t just save time; it results in a better fit and fewer adjustments. Patients love the convenience, and dentists appreciate the precision. It’s a win-win that’s quickly becoming the new standard in restorative care.

From routine check-ups to advanced treatments, we’ve got you covered. If you live in Sydney or near any of our three clinics—Darlinghurst Smiles, Normanhurst Dental, or Chatswood Smiles—you don’t need to look further for all your dental care. Book your appointment today by calling: Darlinghurst Smiles (02 8577 9247), Normanhurst Dental (02 9989 8565), or Chatswood Smiles (02 9412 3666).